- Metal roofing is a long-lasting and durable option for new roofs. The most common and cost-effective types of metal roofing are painted steel, galvanized steel, and aluminum roofing. More costly, but also even longer-lasting options include copper, zinc, and tin.

- Metal roofs offer superior durability, better energy efficiency, and low- to NO- maintenance needs compared to other roofing materials. They will last for 50+ years, compared to a shingle roof at 20-30 years.

- Cost is the primary factor for most people considering a metal roofing system, as a steel roof or other metal panels do cost more up front than standard asphalt shingles. Copper or zinc will cost even more, and they’re usually reserved for luxury settings or for individuals where budget is not an issue.

Metal Roofing Panels Basics

Metal roofing is growing in popularity thanks to an appealing mix of remarkable durability, elegant design diversity, and cost-savings over the long-haul. But for those first considering a metal roof, you might simply be asking what different types of metal and roofing are out there!

Metal roofing systems are highly regarded for their versatility in providing a low-maintenance, durable roof with elegance and aesthetics that work for just about any home.

Boasting a lifespan of 50 years or more, metal roofs are durable and long-lasting, delivering leak protection, fire resistance, weatherproofing benefits, and lower lifetime costs.

Compared to traditional asphalt shingles, which are the cheapest option for a new roof, it does cost a little more to install metal roofs: this is a result of higher material costs, and more labor costs, as metal roofs are more detail oriented.

- A metal roofing panel usually runs the length of the roof pitch. They can be concealed fastener panels, like standing seam metal roofing panels, (which are usually 16” wide panels, or they can have exposed screws, Corrugated panels, which are usually 36” wide, screws each have a waterproof gasket to seal the screw hole from water. A single roof plane may only require 8 to 15 panels, meaning very few seams in the roof surface.

- A shingle, by contrast, is 36-40 inches wide and only 13 inches tall/deep. This means that hundreds of shingles will be needed for each roof pitch during a roof replacement, requiring more labor and creating dozens of possible failure points where the shingles meet or overlap.

The range of commonly available materials for both standing seam metal roofs and corrugated metal roofs include painted steel, aluminum, and galvanized steel – all with their own individual advantages/disadvantages.

Other corrosion resistant and fire resistant metal roofing options include copper, tin, and zinc. These less common and different metal roofing materials are much more expensive than the steel and aluminum roofing material options above.

The Most Common Metal Roofing Materials

The most common metal roofs today are made of painted steel, aluminum, and galvanized steel. All these materials are affordable, durable, and low-maintenance, making them popular choices for residential metal roofing and commercial or agricultural needs alike.

Steel Roofing (Painted Metal)

Steel roofing is popular for its budget-friendly nature, adaptability, and recyclable capabilities. Untreated steel will rust, so it needs a protective coating in order to maintain the material’s durability over time as well as prevent corrosion. This is why painted steel is so common: affordability and dependability.

Painted steel roofs (at least those that we install) have a 35-year manufacturer’s warranty on the paint, meaning that with another coat in a few decades and a little TLC, your painted steel roof could last for generations.

[Read “How Long Does a Metal Roof Last?“]

Aluminum Roofing

Aluminum metal roofing is a powerful option because it is lightweight, rust-proof, and can even help you conserve energy.

An aluminum roof will not rust! Particularly in coastal regions where saltwater contact can cause corrosion damage, aluminum stands out for its resilience. And, aluminum, roofs provide savings on heating/cooling costs; homeowners have reported energy use reductions of around 20%.

On the downside, aluminum is more expensive than painted steel and tends to dent more easily because it is a softer metal.

Galvanized Steel Roofing

Galvanized steel is a sought-after metal roofing material for commercial or agricultural settings because it is highly corrosion and rust resistant. This effect is achieved through a thin zinc coating. This coating creates an oxygen and moisture barrier, extending the lifespan of galvanized steel up to one hundred years with minimal maintenance .

This strength combined with added protection makes it ideal for agricultural buildings or animal enclosures where ammonia can contribute to faster corrosion. It does cost more than painted steel.

Less Common Metal Roofing Materials

Metal roofing materials such as galvanized steel, aluminum and steel are usually the most common choices, yet copper, zinc, and tin offer an alternative, unique look with lasting durability, albeit at a much higher cost.

Copper Roofing

Copper roofing is renowned for its aesthetic appeal, longevity and energy efficiency, and with the right care it can last one hundred years or more. It’s one of the more expensive options among available roofing materials due to a high material cost.

Copper has a golden/brass hue when installed, but it will “patina” over time, adding charm and elegance.

Zinc Roofing

Zinc roofs offer tremendous durability as well as low maintenance requirements. Zinc is far more corrosion and rust-resistant than steel, and small scratches in the material can actually “heal” on their own.

Zinc, like copper, has a very high material cost compared to steel.

Tin Roofing

In the 19th century, tin roofing was a popular choice due to its easy installation and stylized patterns. This material can still be found on homes and barns built in rural areas, but over time the tin roof has been outmoded by more modern metal roofing such as steel or aluminum that provides greater durability against corrosion damage.

Tin roofs may have some areas of application now but are far less common.

Metal Roofing Fasteners

When installing a metal roof, the selection of appropriate fasteners is essential for ensuring both durability and performance.

Two main types are available:

Exposed fasteners – Metal screws are screwed through the panel, screwed into the underlying structure, and the head remains on top of the panels. They have a rubber gasket just below the screw head to prevent moisture or water penetrating the hole. Exposed fastener panels are generally a little less expensive than concealed or standing seam metal roofs.

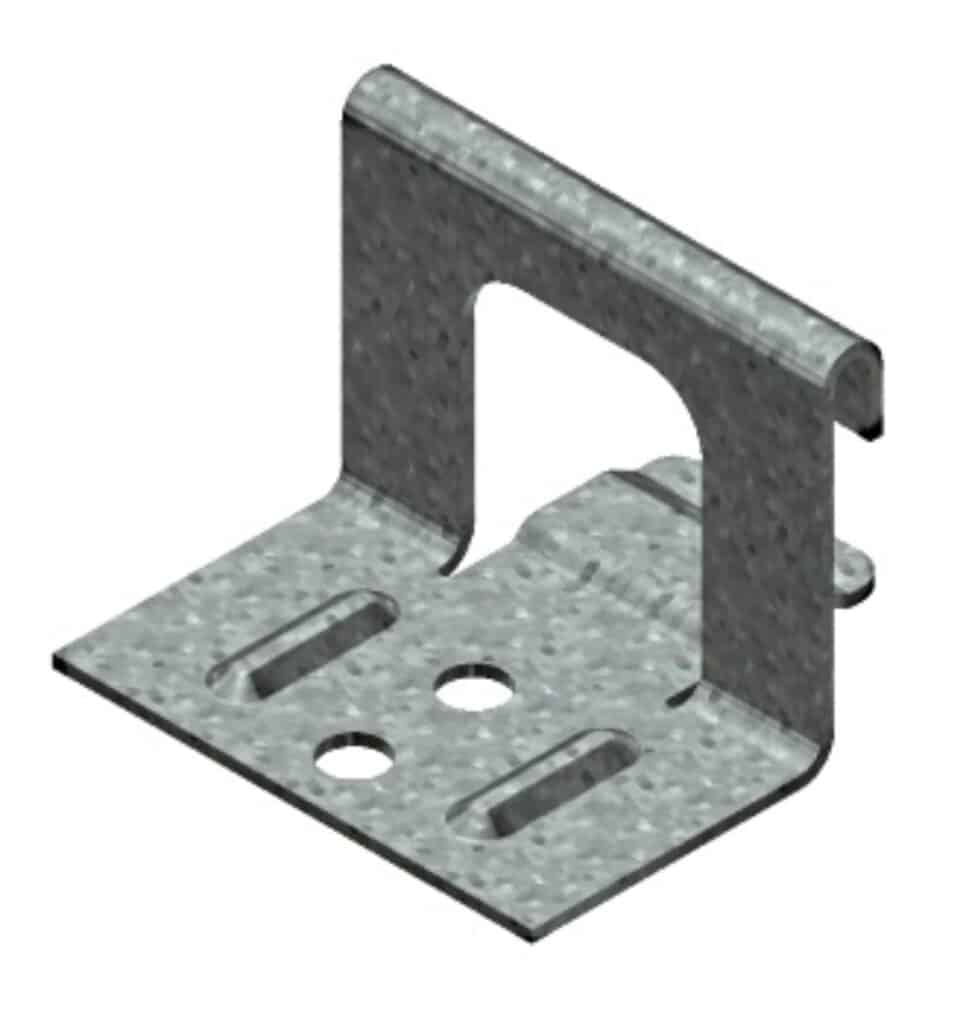

Hidden fasteners – Standing seam metal roofing relies on a locking fastener mechanisms completely concealed below the steel panels. These fasteners are applied to the underlying structure, and the standing seam roof is then “locked” onto the fastener. With a standing seam metal roof, there are no holes through the material, meaning less risk of moisture penetration in the long-run.

Metal Roofing Styles & Profiles

When considering metal roofing for your home or building, there are a variety of styles and profiles to choose from.

Corrugated metal roofing is probably what you think of first. It is widely used on barns throughout the country due to its affordability and durability for both commercial and residential applications. a Corrugated metal roof can have 2-4 “ribs” running along the length of the panel.

Standing seam offers a modern look with vertical panels secured together by raised seams and hidden fasteners. This profile provides an elegant and timeless look.

Factors to Consider When Choosing A Metal Roofing Material

When selecting a metal roofing material, cost is generally the biggest factor. Prices vary based on location and material used. Steel or aluminum will cost less than a copper roof or zinc roofing.

But remember, any metal roof will save you money if you’re in the home or building long enough! They cost more up front, but require fewer replacements and repairs over 30-40 years in the building.

Aesthetic is the second thing people are thinking about. Standing seam roofs will last longer AND cost more up front, but it provides a luxurious look that will have guests ooh-ing and aah-ing! Standing seam roofs look great on both old farmhouses and modern homes.

Environmental Benefits of Metal Roofing

Metal roofing is incredibly durable and requires little maintenance, with the added bonus of significant environmental benefits. Most metal roofs are constructed from recycled materials which can be repurposed at the end of their useful life, helping to reduce waste and conserve resources.

This type of roofing material also tends to reflect sunlight instead of absorbing it like asphalt shingles, leading to lower cooling costs as well as a smaller carbon footprint for your home or business.

These traits make metal roof installation an environmentally-friendly and potentially energy-saving solution that homeowners and builders might consider over traditional asphalt shingle installations.

Comparing Metal Roofing to Other Roofing Materials

Metal roofing provides a great deal of value due to its extended lifespan, superior resistance to extreme weather conditions, and low maintenance needs when compared with other materials such as asphalt shingles.

Although a metal roofing cost might be higher initially than that of some alternatives, looking at long-term performance benefits can make this material an attractive choice for those constructing homes or buildings.

Read all about it in our comparison of the costs of shingles versus a metal roof article.

Frequently Asked Questions

What are most metal roofs made of?

Metal roofs are usually constructed with painted steel, aluminum, or galvanized steel. These materials have been chosen for their durability and long-term performance in residential and commercial applications.

What is the disadvantage of a metal roof?

Metal roofs are more expensive to install than other less expensive roofing material options. Finding an experienced roofing contractor who know how to work with them is a bit more difficult compared to the installation of other types of roofing materials.

What are metal roofs coated with?

Most steel roofs have a paint coating that comes from the factory.

Some are galvanized with a thin coating of zinc to improve corrosion and rust-resistance.

Which is better: galvalume or aluminum?

Aluminum roofing has an advantage over other materials when it comes to areas with high levels of exposure to salt water and humidity. Aluminum is naturally resistant to corrosion and rust, making this a wise choice for regions near the coast or otherwise subject to dampness.

Galvalume is a metal roof panel coating process used by a few manufacturers. The technology comes form BIEC International Inc. It is a steel sheet dipped in a coating of 55% aluminum, 43.4% zinc, and 1.6% silicone. Galvalume is highly respected for its corrosion resistance.

What are the 2 types of metal roofing?

Metal roofing is available in two types: standing seam and corrugated sheet. Both of these are known for their durability, longevity, as well as attractive aesthetic qualities when applied to a building exterior. Standing seam metal roofing stands out from its counterpart due to the seams that run vertically along the panels.